5 Interesting Facts About Damascus Knives

Posted by Best.Buy. Damascus1 on

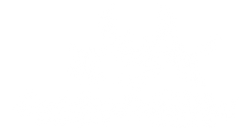

If there's one thing we love, it's Damascus knives. In fact, you'll find several Damascus steel knives in our collection. Damascus knives are not only rich in history but also stunningly beautiful and expertly crafted. For centuries, Damascus steel has been synonymous with luxury and quality, and this is also true of the Damascus knives created today.

We would love to share our enthusiasm for Damascus knives with you, so we have compiled 5 interesting facts about Damascus knives that you will definitely want to hear. Some of them should surprise you unless you are already a collector and historian of Damascus knives.

#1 A Rich History

Damascus knives have a rich history that stretches back centuries. They were first produced 2,000 years ago and are well documented throughout history. Often referred to as the steel of old, they dominated the arms industry for hundreds of years. The first historical reference to Damascus steel was in the 11th and 12th centuries during the Christian Crusades. During these battles, Damascus steel became widely known. You might think that this knife might have originated in Damascus, but in fact, it originated in India, where it is known as Telangana, Wootz, or Ukku steel. From there it came to Damascus, Syria, where it got its name.

#2 Origin Of Damascus Steel

Around the time that Damascus steel originated, Wootz steel was being promoted in the Syrian city of Damascus. Wootz steel was imported from Persia and Sri Lanka and was used to make weapons in Syria. Their incredible strength and quality made them quite popular. It is their use in battle that makes their history so fascinating, but it is the technology of making this knife that is really interesting. Whether you believe it originated in 500 AD or was discovered in Syria, this steel is simply outstanding. Understandably, any knife with a Damascus steel blade is something that you should respect and invest in.

#3 Unique Design

What makes Damascus knives so beautiful is the stunning, distinctive pattern that runs along the blade. The rustic, watery pattern is not only the result of the Damascus steel but also of the manufacturing process. Although the metal produced today is not quite Damascus steel, it is still formed using billet welding, which gives it the multi-patterned design we see in quality Damascus knives today.

Damascene welding involves mixing different alloys of steel and/or iron by first welding them together and then repeatedly folding the total mass, resulting in alloys of different shades that are fused in layers. The welding process can be modified to produce different patterns.

#4 How It Is Made

Pattern-welded steel is made by layering iron and steel and forging the metals together, hammering them at high temperatures to form a welded joint. It can also be called billet welding, which combines different alloys, welding them together and then forming several folds to produce the unique marbled Damascus knives. The joint is sealed with flux to prevent oxygen ingress. The steel is heated to a temperature of between 1500- and 2000-degrees Fahrenheit, which is between 850 and 1100 degrees Celsius.

#5 Modern Techniques

The original method of forging Damascus steel knives quickly led to the invention of a new process that reduced labour consumption and costs. The Damascus produced is called model-welded steel. Forging, which consists of stacking two pieces of metal and pounding them until they become one. The layers result in a pattern similar to that of the original Damascus steel.

Conclusion

Damascus steel and Damascus knives are very special to us, not only because of their history but also because of the way they are made. Each piece and each pattern are lovingly and masterfully crafted to produce a razor-sharp multi-purpose blade that will last for decades. You really can't have too many of these knives in your collection! Visit our website for our pattern welded Damascus knives.